CAMDAC Engineering specializes in services for Independent Test Laboratories and Manufacturing R&D Departments.

We can increase efficiency and accuracy in your lab by automating tasks.

Are you developing a new product and need to show it can withstand thousands of cycles of use without failure?

Need to test the strength of your product but there's no standard fixture your lab can use?

Need to quantify your product's performance using measurments such as stress, strain, pressure, continuity, resistance, temperature, or other?

Need to run a process or test at extreme or precise temperature, humidity or other conditions?

CAMDAC Engineering can build a custom, automated test machine or fixture exactly suited to your unique needs.

We select the right sensors, data acquisition modules, actuators, and motion-control components for your project and combine them with custom LabVIEW-based software so that you'll be able to gather, analyze, and report all the data you need.

CAMDAC designs and builds machines and fixtures for:

- Durability and Reliability

- Strength

- Product Performance

- Fatigue

- Design Validation and Verification

- Safety

- And more...

You'll save time and money:

- By running tests yourself with a customized test machine or fixture made by CAMDAC.

- On design and fabrication, even if you'll be using a third-party laboratory - by taking your CAMDAC-built fixture to the lab for the test.

Get in touch to find out how CAMDAC can help. We're responsive, experienced, and imaginative.

Some Examples:

Problem solved for an independent test lab:

Need: Fixtures to perform ASTM D2990 tensile creep tests with the following requirements:

-

compact design to fit limited space

-

applies constant load of up to 200 pounds to each specimen

-

automatic recording of strain measurements at specified intervals

CAMDAC's solution:

-

compact fixture using lever arms to multiply the force of hanging weights

-

custom data acquisition application created with LabVIEW for automated recording of strain measurements

-

best commercial strain data acquisition module selected

-

software drivers and hardware wired and configured

-

shock absorbing lever-arm support in case of specimen rupture

Problem solved for Nordson Medical

Need: Life cycle test machine to repeatedly connect and disconnect tubing couplings with requirements including:

- benchtop size and easy to set up and run tests

- able to independently run tests on 3 sets of 5 couplings each

- adjustable travel, speed, number of cycles

- self-aligning mechanism

- ability to detect failure to connect or disconnect

CAMDAC's solution:

- stepper motors and linear slides for precise motion

- PLC-based control and touch-screen HMI for simple and reliable operation

- sliding racks for easy access to each set of test stations

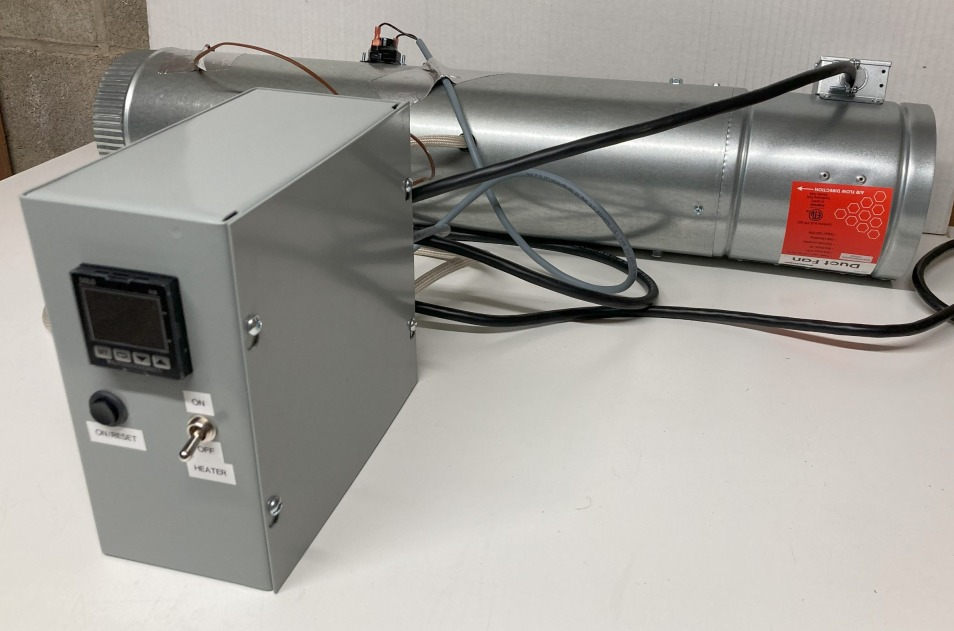

Problem solved for an independent test laboratory:

Need: An unusual test program required hot air, up to 250F, be circulated through a section of pipe. This required consideration of:

- safe operation of heater

- steady temperature control

- display and recording of temperature at 16 locations

CAMDAC's solution:

- custom built PID control box

- temperature switch to shut off heater in case of fan or control failure

- strip heater sized and installed in metal duct section

- installation of heater in client's test setup

-

placement of thermocouples and configuration of data acquisition computer